Prototyping

2014 Series of 1:1 prototyping exercises within the Architectural Association's Design Research Laboratory

Tutor:

Rob Stuart-Smith

In order to address our strategy of infilling urban blocks in China, we proposed a system that could be quickly deployed and bespoke fabricated.

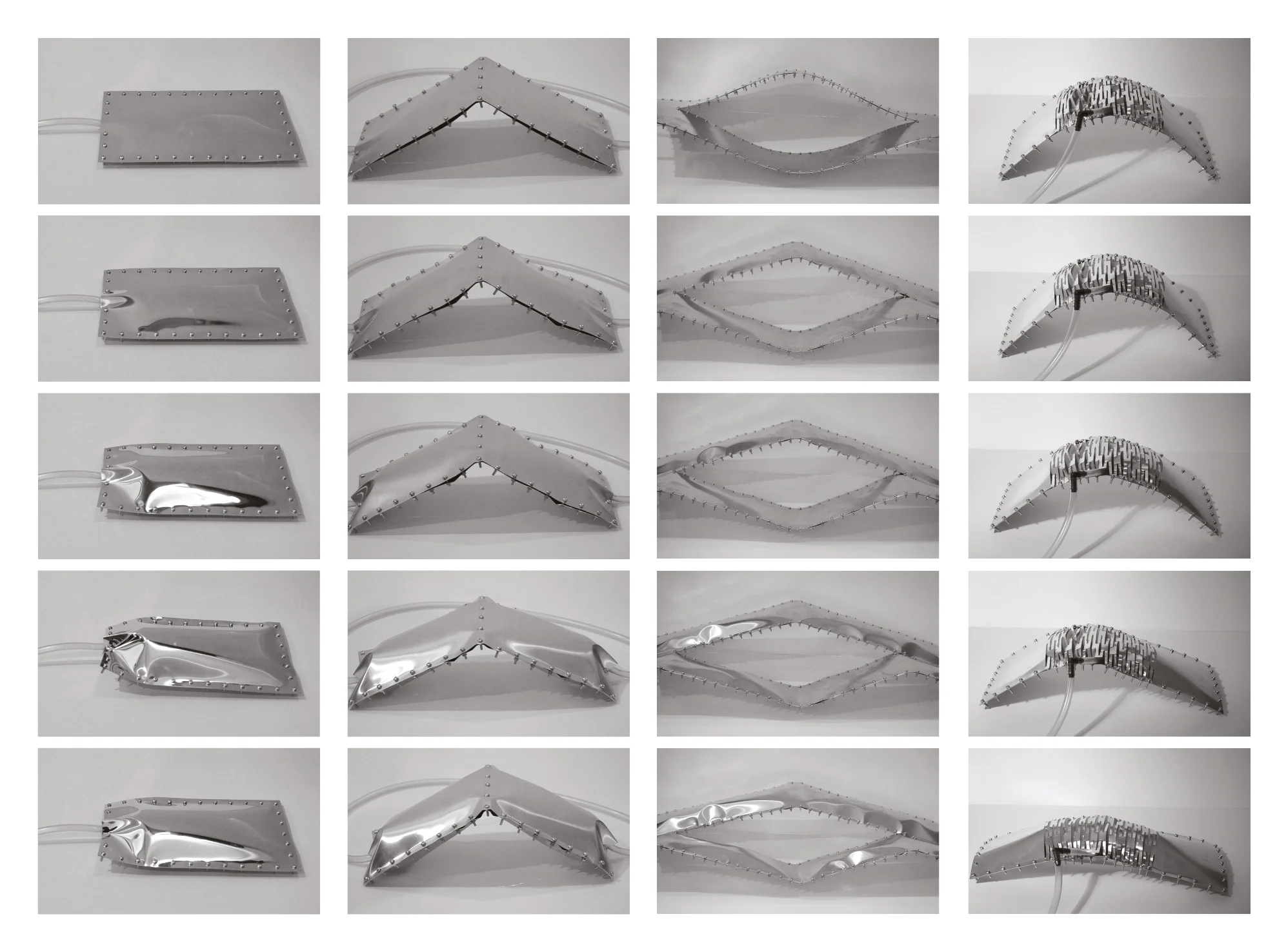

We proposed a flat system of thin metal sheets that are tailored and patterned to expand and occupy the site: these sheets transform into columns, courtyards, façade components or stairs according to the way they are patterned and responding to inflation of soft membranes within them that are used for deployment and, in some cases, rigidised afterwards to form enclosure.

The team set to the challenge to produce a series of iterations of 1:1 prototypes of key sections of the building structure in order to progress the design.

Generating structures from flat sheets raises two main structural problems:

FLAT STRANDS of any material wold collapse under very small axile stresses because of buckling.

FLAT JOINTS have no stiffening elements and therefore the structure would become a mechanism and collapse back to its flat state under small loads.

In order to address the BUCKLING in axile stressed structures the moment of inertia of the section has to be increased in both axis, which is why we use H, T or circular section columns in the building industry. The way we propose to increase the moment of inertia and give structural depth to our flat strands relies on research carried on at the beginning of our thesis on pneumatics. By joining two sheets of aluminium and pumping air at 12 bars inside we deform the aluminium strands so that they become tubes.

The issue around inflatables is the difficulties related with controlling the end geometry , specially when the initial shape is complex. That is why it is a reasonable strategy for the straight parts of our structure but not for the joints of several strands.

In order to create structural depth in joints and also add stiffness to them to avoid the collapse back of the structure, we started a series of proto- types of different angles at 1:1 scale using a variety of techniques that included cut patterns, folding, inflating and riveting. The only rule we set ourselves is that any detail had to be embedded on the main sheets and the rivets joining sheets together were the only material to be added.

Team:

Michael Barraclough

Matthew Le Grice

Daniel Ovalle Costal

José Pareja Gómez